1966

1966Sichuan Air Separation Plant Factory was established as a specialized air separation unit manufacturer in Zigong, Sichuan, China.

1967

1967The factory moved to Jianyang, Sichuan, China.

1971

1971The factory made the first air separation plant with a capacity of 1000Nm3/h.

1983

1983By forming its own sales team, the factory was no longer just a production-only factory, but a supplier with services.

1984

1984The 400m3 cryogenic storage tank was successfully made.

- 1987

The factory obtained pressure vessel design and manufacture certificate (A Class).

- 1990

The factory got ASME certificate and U, U2 stamp issued by the National Board of Boiler and Pressure Vessel.

- 1991

Hangzhou Chuankong General Equipment Co., Ltd was established.

- 1996

Sichuan Air Separation Plant (Group) Co., Ltd (SASPG) was named, including Sichuan Air Separation Plant Factory, Jianyang Heat Exchange Factory, Sichuan Hemispherical Vessel Head Manufacturing Co., Ltd., and Sichuan Jianyang Chahu Air Separation Technology Development Center.

- 1997

SASPG cooperated with Air Liquide for the development of 6000Nm3/h air separation plant.

- 1998-2000

SASPG cooperated with Praxair, and this period witnessed the quick technical development of SASPG.

- 2001

SASPG transformed from a state-owned company to a joint stock company.

- 2005

The 28000Nm3/h air separation unit was developed with out patent technology.

- 2010

Zhejiang Dachuan Air Separation Plant Co.,Ltd. was established in Huzhou, Zhejiang, fully held by SASPG.

- Till 2013

Now SASPG has 40 subsidiary companies and holding companies. We have produced more than 2000 sets of air separation plants, more than 8000 pieces of cryogenic storage tanks, more than 100 sets of CO2 generators, etc. They were delivered to customers in more than 50 countries.

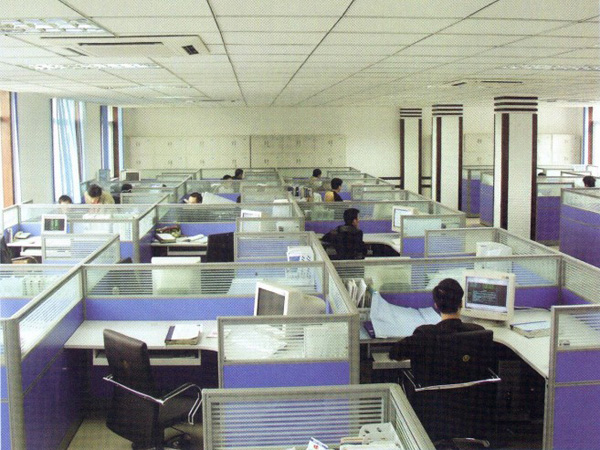

Company Tour

We have 15,000 square meters of office buildings, including conference rooms, the marketing office, technical office, etc. We also have clean canteen, dormitory and staff room for employees.

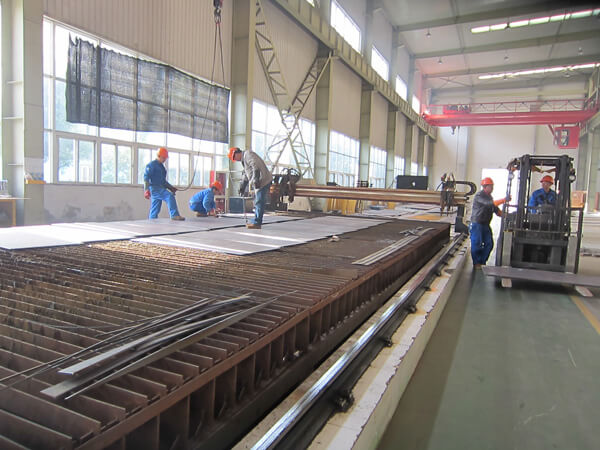

We have 17 pieces of 5T-160T cranes and 25 pieces of roller carriers. The maximum lifting size is 35×4.5m, and the maximum lifting weight is 2×160T. Large workpieces can be easily moved from one side to the other side of the workshop in a fast speed.

We implement a testing standard that is higher than the national one, to ensure that every product has a long service life. We have hydrogen mass spectrometer leak detector, impact testing machine, tensile testing machine, metallographic analyzer, nondestructive testing equipment, etc. We also have a complete inspection and testing plan, and all the inspection records and test reports are complete and traceable.

Our new factory is located at the band of the Beijing-Hangzhou Grand Canal. We have our own private basin wharf in a size of 46m×16m×8m (l×w×h). When the production is completed, the finished equipment can be lifted aboard directly from the workshop and transported by river to Shanghai or other ports (150km from Shanghai port). The river transport can go beyond restrictions on large pressure vessels of land transport. Even the 600m3 tank can be easily and quickly delivered to the port.

a. Suppliers: TISCO, Baosteel,Huzhou Jiuli, Zhejiang Zhongda, Zhangjiagang Huafu, Xinyang Sanyuan, Hangyang, Wuxi KOSO.

b. Quality control and tracking procedures: raw material sourcing, supplier assessment, data review, chemical analysis, and mechanical test. Every step is strictly conducted in line with company standards.

c. Material testing and identification (procedures, methods, and equipment): quality manual; procedure document; standards such as codes of pressure vessel, GB150, GB18443, GB35311 and ASME; a variety of models of physical-chemical devices.

a. Cutting machine: we have the world-leading digital underwater plasma cutting machine, which features high efficiency and small deviation.

b. Bending machine: we have 10 high precision bending machines with a deviation less than 50mm.

c. Planer: 12 meters at one stroke.

d. Welding machine: we have 12 automatic welding machines, 10 AC welding machines, 1 all-position welding robot. We are also proud to have 35 senior welders with years of experience.

Safety inspection coverage: productionsite, personal protective equipment, surroundings, emergency ambulance, fire safe passage, etc.

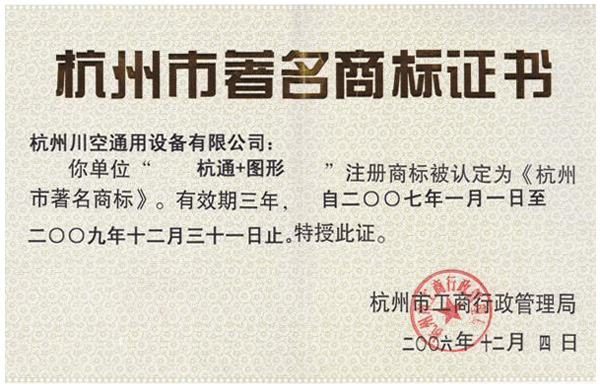

Our Certificates

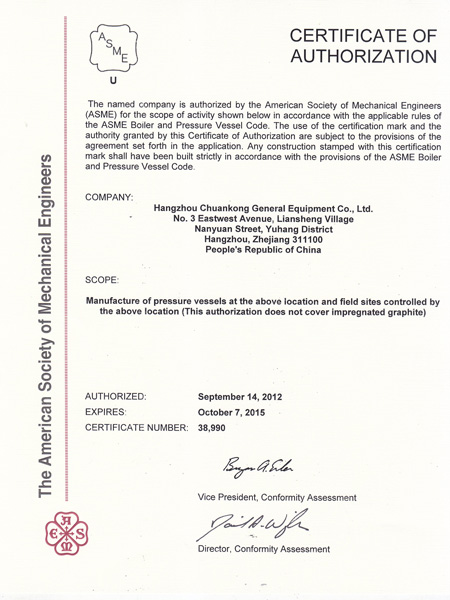

ASME Certificate

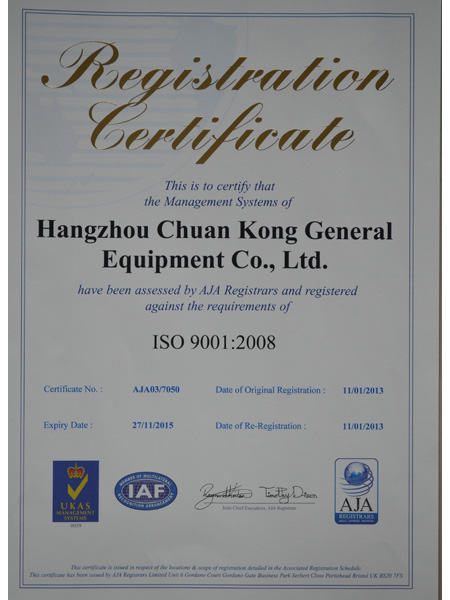

ISO 9001:2008 Certificate

Manufacture License of Special Equipment

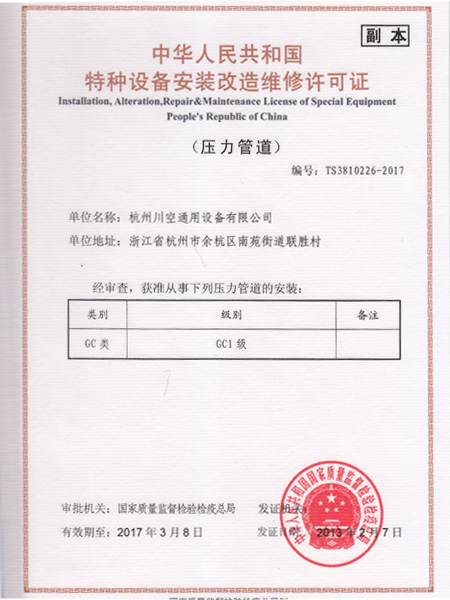

Installation, Alteration, Repair and Maintenance License of Special Equipment

The National Board of Boiler and Pressure Vessel Inspectors Certification of Authorization

Certificate of National Key Project

Certificate of Zhejiang Name Brand