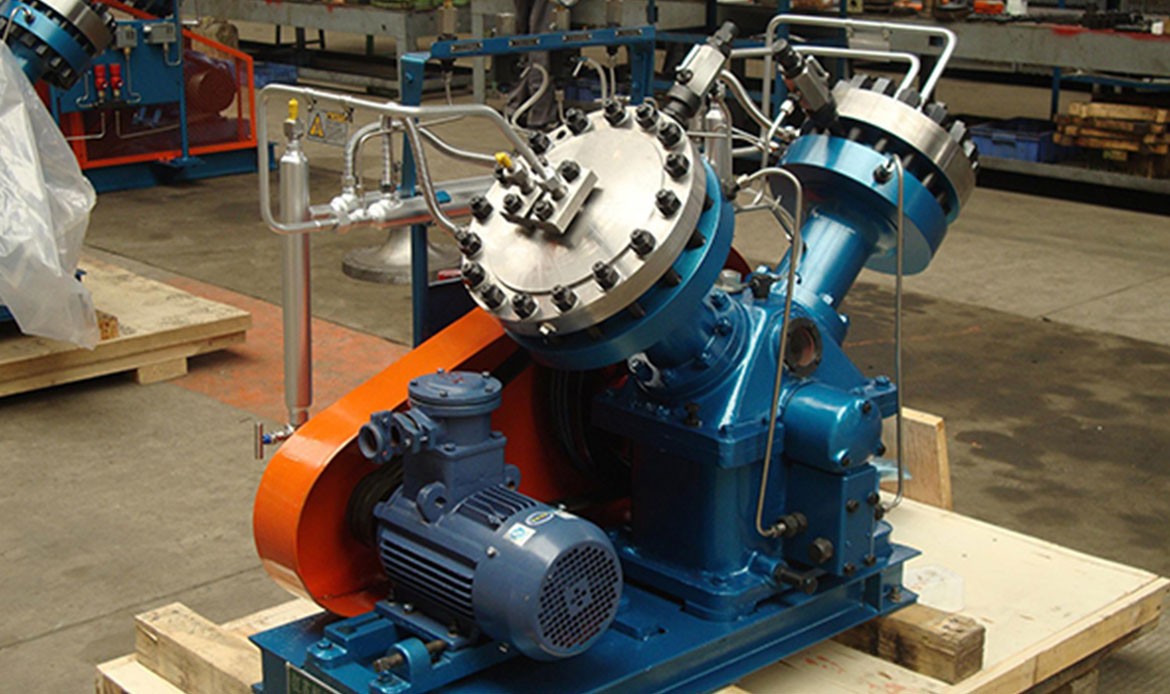

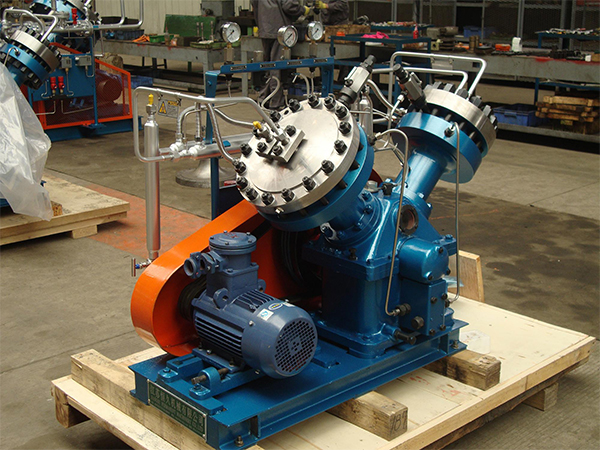

Diaphragm Compressor

The diaphragm compressor is a positive displacement compressor due to its special structure. While its cylinder does not require lubrication and has good sealing performance. Because the compact medium is not in contact with any lubricant. Therefore, in the compression process, there will be no risk of pollution. So the machine is qualified to compress gases with high purity. Besides, it is a variant of reciprocating compressor.

Description

Applications

The diaphragm compressor is particularly suitable for compressing, transporting, and bottling precious and rare gases. It is also an ideal air compressor for handling highly corrosive, toxic, inflammable, explosive, radioactive gases.

The main applicable occasions are as following: gas filling/mixing/conveying, tanker loading, chemical and petrochemical gas processing, gas for electronic, semiconductor and fibre manufacturing, one-stop gas compression and storage, booster of gas recycling system, high pressure gas storage, hydrogen system of power plant, hydrogen supply system, supercritical fluid and solvent extraction system, research and development.

Purchasing Guide

Please read the following before purchasing the diaphragm compressor:

1. applicable medium: such as high-purity gases, inert gases, flammable gases, toxic gases, and other special gases;

2. both the inlet pressure and discharge pressure are gauge pressures;

3. When making inquiry or placing order, it is necessary to provide the following information:

a. inlet pressure;

b. discharge pressure;

c. volume flow;

d. medium to be compressed;

e. other requirements.

Note: When compressing special media, please also provide the component information and physical-chemical properties of the medium.

Model List and Technical Parameters

Z type

| Model | GZ-10/4-16 | GZ-15/15-20 | GZ-5/5-20 |

|---|---|---|---|

| Compression stage | one-stage | one-stage | one-stage |

| Cooling water consumption (t/h) | 0.5 | 0.8 | 0.8 |

| Air discharge (Nm3/h) | 10 | 15 | 5 |

| Inlet pressure (Mpa) | 0.4 | 1.5 | 0.5 |

| Outlet pressure (Mpa) | 1.6 | 2 | 2 |

| Dimension (L×W×H)(mm) | 1230×600×1100 | 1000×560×1100 | 1520×810×1170 |

| Weight (t) | 0.5 | 0.6 | 0.8 |

| Motor power (Kw) | 2.2 | 2.2 | 3 |

V type

| Model | GV-8/8-160 | GV-20/3-200 | GV-5/200 |

|---|---|---|---|

| Compression stage | two-stage | two-stage | two-stage |

| Cooling water consumption (t/h) | 1.2 | 0.4 | 4.5 |

| Air discharge (Nm3/h) | 8 | 20 | 5 |

| Inlet pressure (Mpa) | 8 | 0.3 | atmospheric pressure |

| Outlet pressure (Mpa) | 16 | 20 | 20 |

| Dimension (L×W×H)(mm) | 1310×686×980 | 2030×1125×1430 | 1500×780×1080 |

| Weight (t) | 0.65 | 1.8 | 0.75 |

| Motor power (Kw) | 3 | 15 | 3 |

L type

| Model | GL-40/200 | GL-150/6-200 | GL-580/11-25 |

|---|---|---|---|

| Compression stage | two-stage | two-stage | two-stage |

| Cooling water consumption (t/h) | 4.5 | 5 | 5 |

| Air discharge (Nm3/h) | 40 | 150 | 580 |

| Inlet pressure (Mpa) | atmospheric pressure | 0.6 | 1.1 |

| Outlet pressure (Mpa) | 20 | 20 | 2.5 |

| Dimension (L×W×H)(mm) | 3675×1750×1970 | 3475×1350×2300 | 3675×2000×2340 |

| Weight (t) | 3.8 | 5 | 5.8 |

| Motor power (Kw) | 30 | 45 | 30 |

D type

| Model | GD-150/0.01-7 | GD-120/1-200 | GD-600/12-40 |

|---|---|---|---|

| Compression stage | two-stage | two-stage | two-stage |

| Cooling water consumption (t/h) | 5 | 5.5 | 6 |

| Air discharge (Nm3/h) | 150 | 120 | 600 |

| Inlet pressure (Mpa) | 0.001 | 0.1 | 12 |

| Outlet pressure (Mpa) | 0.7 | 20 | 4 |

| Dimension (L×W×H)(mm) | 4200×3400×2000 | 3500×2300×1500 | 500×2300×1550 |

| Weight (t) | 13.8 | 8.5 | 8.5 |

| Motor power (Kw) | 45 | 55 | 55 |

Shipping & Delivery

The transportation of large equipment, such as the air separation unit, PSA gas plant, and the CO2 recovery plant, has always been a concern of overseas customers. The unloading and lifting must be careful. How to reduce extra handling fees is also one of the issues to be taken into consideration.

We can provide you with a worry free delivery:

1. We maintain long-term cooperation with some partner forwarders. So we can:

a. tell the accurate shipping date and quote the best shipping rates

b. book appropriate cargo space and choose the best shipping method: container, roll-on-roll-off ship, open top container or bulk carrier

c. make appointment for commodity inspection, arrange shipment, and prepare necessary documents for customs clearance

2. We have our own private wharf. Even 300m3 pressure vessels can be loaded within the factory and sent to Shanghai port.

3. We are quite experienced in loading and fixing containers, protecting the cargo from any possible damage on the way. The cargos will be in perfect condition upon the arrival at the destination.

4. The bulk ship and roll-on-roll-off ship are for the delivery of large and bulky cargos. The destination port may not be equipped with large cranes, and at somewhere the lifting charges are quite expensive. Taking these factors into consideration, we will choose ships equipped with cranes to reduce costs for customers. Our forwarder will arrange appropriate crane lifting and attach the cargo to the deck or cabin.

5. We will track the delivery until you receive the cargo.

6. The vast majority of customers receive cargos intact, but there is still likeliness of slight painting scratches. In this occasion, we suggest customers to fix the paint on their own if necessary. In addition, customers may purchase transport insurance to further reduce the risk of cargo damage.

-

Date

-

Category

-

Tags

-

Share