Dry Ice Making Machine

We are committed to the research and production of the novel dry ice making machine which features low energy consumption, good appearance and operation simplicity. To meet diversified needs of customers at home and abroad, our experienced production team has created many kinds of special dry ice makers to make dry ice in various shapes (in particles or blocks).

Description

1. Dry ice manufacturing process:

LCO2 cryogenic storage tanks or dewar flasks (with hose connecting the outlet of tank and the inlet of dry ice machine)-dry ice making machines (available for direct use after leaving the factory) – dry ice chest

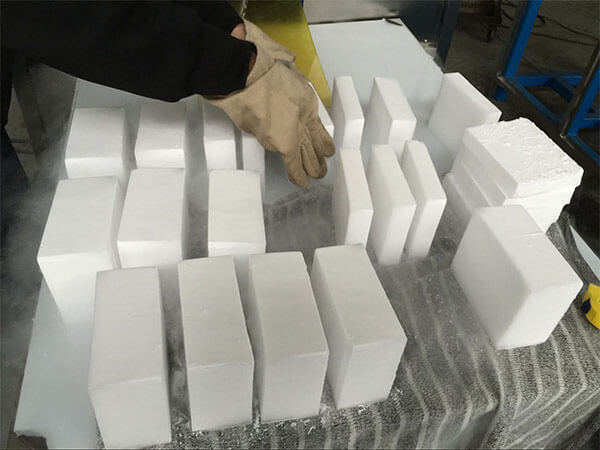

2.Size of dry ice

a. Block: cuboids, the international standard cross-sectional area of 125×105mm, the adjustable thickness of 15-50mm, a customized size of 350×350mm is also available.

b. Particle: Φ1.5mm, 2mm, 3mm

Purchasing Guide

If you would like to buy our dry ice making machine, please advise us of your requirements on the output, shape, and size. We also provide one-stop service by offering the following supporting products:

Ancillary equipment for dry ice machine

Cryogenic liquid storage tank – medium: LCO2; capacity: 10-15m3

Dewar flask – medium: LCO2; capacity: 210L, 495L; vertical or horizontal type

Dry ice chest – capacity: 50L, 250L, 310L

Model Lists

Model Lists

Series 1

Dry ice yield: 40% (based on different CO2 temperatures, there may be a slight change in yield)

Pro{overflow: hidden;margin-bottom: 2em;margin-top: 3em;}.pro_img{float: left;width: 30%;}.pro_message{float: right;width: 68%;}

Model: CKDP-P50 in particles

Output: pellet dry ice, 50kgs/hr

Power: 3 KW

Power supply: 380V, 50-60Hz, 3-phase

Dimension of the whole machine (mm): 1100×600×1200

Weight: 400 kgs

Model: CKDP-P70 in particles

Output: pellet dry ice, 100kgs/hr

Power: 3.7 KW

Power supply: 380V, 50-60Hz, 3-phase

Dimension of the whole machine (mm): 1190×600×1300

Weight: 500 kgs

Model: CKDP-P150 in particles

Output: pellet dry ice, 200kgs/hr

Power: 11 KW

Power supply: 380V, 50-60Hz, 3-phase

Dimension of the whole machine (mm): 1700×1000×1800

5. Weight: 1000 kgs

Model: CKDP-P270 in particles

Output: pellet dry ice, 300kgs/hr

Power: 15.5 KW

Power supply: 380V, 50-60Hz, 3-phase

Dimension of the whole machine (mm): 1950×1100×2000

Weight: 1500 kgs

Model: CKDP-P400 in particles

Output: pellet dry ice, 400kgs/hr

Power: 15 KW

Power supply: 380V, 50-60Hz, 3-phase

Dimension of the whole machine (mm): 1750×1350×1700

Weight: 2100 kgs

Model: CKDP-P500 in particles

Output: pellet dry ice, 540kgs/hr

Power: 15.5 KW

Power Supply: 380V, 50-60Hz, 3-phase

Dimension of the whole machine (mm): 1950×1250×2000

Weight: 2000 kgs

Model: JBGY-100-01 in blocks

Output: block dry ice, 120-185kgs/hr

Power: 7.5 KW

Density: ≥1.483.

Power Supply: 380V, 50-60Hz, 3-phase

Dimension of the whole machine (mm): 1430×1100×1600

Weight: 1200 kgs

Model: CKDB-B500 in blocks

Output: block dry ice, 500kgs/hr

Power: 15.5 KW

Power Supply: 380V, 50-60Hz, 3-phase

Dimension of the whole machine (mm): 2050×1100×2000

Weight: 1800 kgs

Shipping & Delivery

The transportation of large equipment, such as the air separation unit, PSA gas plant, and the CO2 recovery plant, has always been a concern of overseas customers. The unloading and lifting must be careful. How to reduce extra handling fees is also one of the issues to be taken into consideration.

We can provide you with a worry free delivery:

1. We maintain long-term cooperation with some partner forwarders. So we can:

a. tell the accurate shipping date and quote the best shipping rates

b. book appropriate cargo space and choose the best shipping method: container, roll-on-roll-off ship, open top container or bulk carrier

c. make appointment for commodity inspection, arrange shipment, and prepare necessary documents for customs clearance

2. We have our own private wharf. Even 300m3 pressure vessels can be loaded within the factory and sent to Shanghai port.

3. We are quite experienced in loading and fixing containers, protecting the cargo from any possible damage on the way. The cargos will be in perfect condition upon the arrival at the destination.

4. The bulk ship and roll-on-roll-off ship are for the delivery of large and bulky cargos. The destination port may not be equipped with large cranes, and at somewhere the lifting charges are quite expensive. Taking these factors into consideration, we will choose ships equipped with cranes to reduce costs for customers. Our forwarder will arrange appropriate crane lifting and attach the cargo to the deck or cabin.

5. We will track the delivery until you receive the cargo.

6. The vast majority of customers receive cargos intact, but there is still likeliness of slight painting scratches. In this occasion, we suggest customers to fix the paint on their own if necessary. In addition, customers may purchase transport insurance to further reduce the risk of cargo damage.

-

Date

-

Category

-

Tags

-

Share

Related Projects